At this very moment, somewhere on your plant floor, a disengaged worker is going through the motions, a near-miss is going unreported, and critical tribal knowledge just walked out the door with a retiring technician. Your dashboards won’t show any of this until it’s too late.

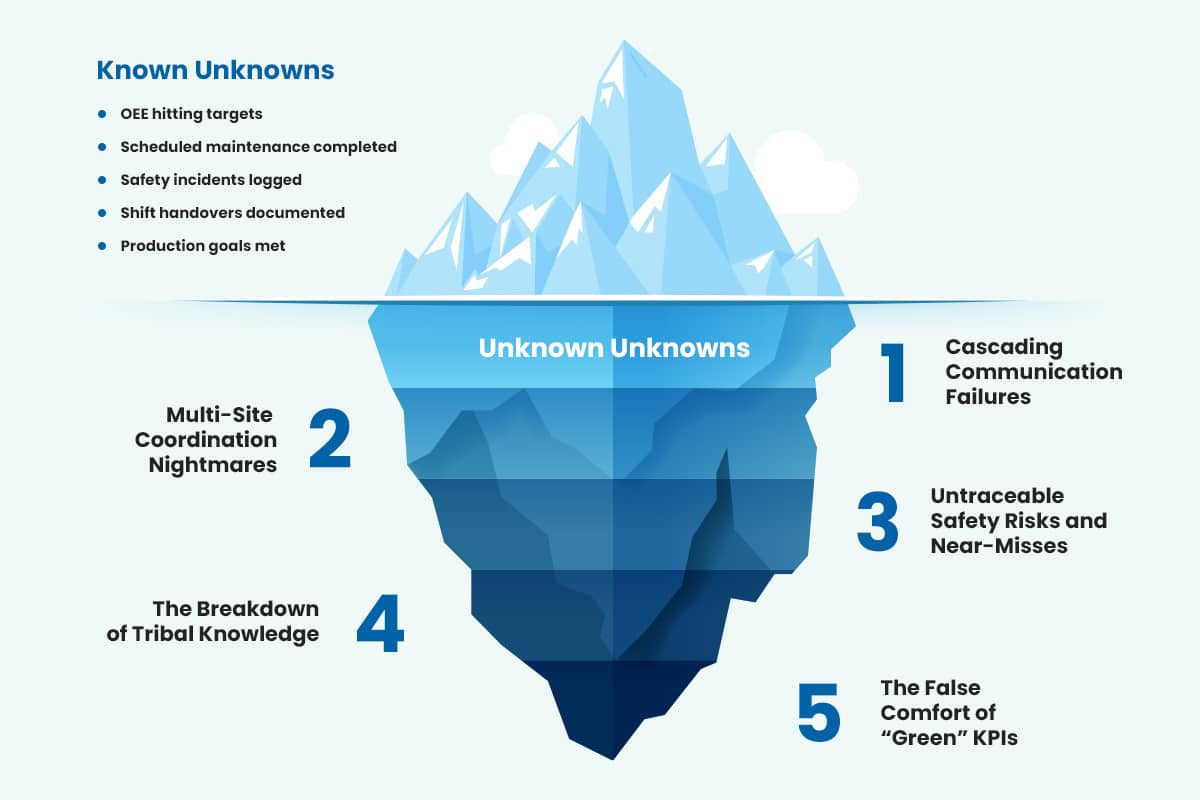

Like the infamous iceberg that sank the Titanic, the most dangerous threats to your manufacturing operation aren’t the ones you can see. While your KPIs might be in the green and your scheduled metrics hit their targets, 70% of your actual operational problems are lurking beneath the surface — invisible to traditional monitoring systems but very real in their impact on safety, productivity, and profitability. We call this the operational iceberg, and it’s full of known unknowns and worse, unknown unknowns.

The fundamental problem? Every traditional communication system treats frontline conversations as temporary noise instead of permanent operational intelligence.

Key highlights:

- A traditional communication system is a set of legacy tools that enable instant messaging but leave no trace for follow-up, accountability, or improvement

- Surface-level metrics give the illusion of control, but without visibility into real-time communications and delays, you miss the root causes driving downtime

- The Walt® Smart Radio System by weavix® is the only manufacturing communication system that captures, transcribes, and timestamps every frontline conversation, turning daily conversations into a permanent source of operational insight

What Is a Traditional Communication System?

A traditional communication system is a set of legacy tools — analog radios, landlines, and intercoms — designed for real-time exchanges that vanish the moment they happen.

These systems assume that if something matters, it will get written down later. But that’s not how frontline communications work. When you don’t capture conversations, you lose the chance to revisit, track, or act on them. That means no data, no accountability, and no improvement.

What’s Above the Waterline: The 30% You Can See

Traditional manufacturing visibility focuses on what’s easily measurable:

| Metric | What This Metric Means in Traditional Manufacturing |

|---|---|

| OEE hitting targets | Machines running, parts produced |

| Scheduled maintenance completed | Work orders closed on time |

| Safety incidents logged | Reportable events documented |

| Shift handovers documented | Paperwork filed properly |

| Production goals met | Daily/weekly targets achieved |

These metrics create a false sense of security. Everything appears to be running smoothly because it’s on the surface. But they only tell you what happened, not what’s happening or what’s about to happen.

As a Facilities Operation Supervisor at Panasonic Energy, puts it: “For every issue we get called about, it can be 30 minutes before technicians can even start work — if they have every piece of equipment already on hand. Then add another 30 minutes for diagnosis. So I potentially have an hour worth of downtime before I even attempt to fix it.”

That hour of hidden delay? It disappears into the void that traditional communication channels like radios, phones, and text messaging systems create — leaving you blind to what actually caused the problem.

What’s Below the Waterline: The 70% That Traditional Communication Solutions Can’t Capture

Traditional communication solutions miss more than they capture. Here’s what’s hiding underneath, and why it’s costing you.

1. Cascading Communication Failures – The #1 Hidden Killer

The Problem: A single missed or misunderstood message during a shift change can trigger hours of lost production without anyone tracing it back to the original communication breakdown.

Why Traditional Communication Systems Fail: Standard radios, phones, and messaging platforms create what we call “communication black holes.” When critical information is shared over traditional push-to-talk radios or phone calls, there’s no permanent record, no ability to verify what was actually said, and no way to trace the root cause when delays occur.

To go back to the example we mentioned at Panasonic Energy, their challenge is massive because their space is massive: it’s a 4.7 million square foot EV battery facility, with 50 technicians responsible for over 2,000 critical assets. One miscommunication can cascade across the entire operation. Traditional two-way radio systems would leave them completely blind to these failure points.

The Walt Difference: Only weavix’s Walt® Smart Radio System with AI-powered dictation, transcription, and timestamping creates a permanent, searchable record of every operational communication that occurs. When issues arise, there’s no ambiguity — just a clear timeline of who said what, when, and to whom. This isn’t just better record-keeping; it’s the difference between recurring problems and true root cause elimination.

2. Multi-Site Coordination Nightmares

The Problem: Companies with multiple facilities struggle to maintain consistent communication standards, share best safety practices, and coordinate cross-site operations. Language barriers make this exponentially worse.

Why Traditional Communication Systems Fail: Standard communication tools operate in silos. A breakthrough safety procedure discovered at your Ohio plant stays trapped there. Spanish-speaking workers at your Texas facility can’t benefit from insights shared by English-speaking teams in Michigan.

The Walt Difference:

Walt is the only manufacturing communication system with real-time translation across 100+ languages, enabling seamless knowledge sharing across global operations. When a maintenance insight is discovered in Detroit, it’s instantly accessible and actionable in Tijuana, Mumbai, or São Paulo. This transforms your entire network into a learning organization instead of isolated islands of knowledge.

Keep reading: See the top workplace communication barriers to overcome in 2025 and beyond

3. Untraceable Safety Risks and Near-Misses

The Problem: For every safety incident that gets reported, there are dozens of near-misses that disappear into the communication void.

Why Traditional Communication Systems Fail:

When a worker spots a potential hazard and mentions it over a standard radio or in passing conversation, that critical safety intelligence vanishes. There’s no way to capture, categorize, or act on these observations systematically.

The conversation is dust.

At Howard Industries’ 2.4 million square foot electrical equipment facility, their VP of IT told us that their previous communication system actually created additional safety risks through distracting external communications.

The Walt Difference:

Walt’s dedicated, permission-based safety channels with voice communication, photo, and video reporting make hazard documentation frictionless. But here’s what no other system can do: Walt automatically transcribes every message. This transforms safety from reactive damage control to proactive risk elimination.

Keep reading: Discover how a multimedia messaging service benefits your frontline

4. The Breakdown of Tribal Knowledge

The Problem: When experienced workers leave, their undocumented knowledge about equipment quirks, process shortcuts, and maintenance workarounds vanishes with them.

Why Traditional Communication Systems Fail: Informal knowledge sharing happens in hallway conversations, quick explanations, and demonstrated techniques that traditional communication tools can’t capture or preserve.

The Walt Difference: Walt is the only system that automatically captures and archives tribal knowledge as it happens naturally. When a veteran technician explains a troubleshooting technique over Walt, it’s not just heard — it’s transcribed, timestamped, tagged by equipment type, and available forever for future reference. This creates a living, growing knowledge base that preserves institutional wisdom permanently.

5. The False Comfort of “Green” KPIs

The Problem: Your operational dashboards may indicate smooth performance while critical inefficiencies remain invisible.

Why Traditional Communication Systems Fail: Standard KPIs measure outcomes, but they can’t reveal the communication delays, repeated explanations, and coordination failures that create hidden friction in your operations.

The Walt Difference:

Walt provides the only digital communication platform that reveals the story behind your metrics. While your dashboards show “task completed,” Walt shows you the three communication delays, two clarification requests, and one safety concern that happened along the way. This context transforms reactive management into predictive optimization.

Every single of our customers relies on this, and can’t believe they never had it before.

Why Only Walt Can Make the Invisible Visible

The fundamental reality: Every traditional communication solution treats frontline conversations as temporary exchanges. Walt treats them as permanent operational data.

Let’s look at the four pillars that make Walt unique.

1. AI-Powered Transcription at Manufacturing Scale

Every word spoken is automatically transcribed and archived/Works in noisy industrial environments where speech recognition typically fails. Walt creates a permanent record for root cause analysis and continuous improvement. No other manufacturing communication platform offers this capability.

2. Real-Time Translation Across 100+ Languages

Walt breaks down language barriers that fragment operations, preventing full orchestration of communications. Our smart radio enables knowledge sharing across global manufacturing networks. Walt ensures safety-critical information reaches every worker in their native language. This level of translation capability simply doesn’t exist in traditional industrial communication.

Keep reading: Understand how AI translation transforms manufacturing operations

3. Precision Timestamping for True Accountability

Every communication is tagged with exact time, location, and participants. Walt enables forensic analysis of operational delays and safety incidents by creating an audit trail for compliance and continuous improvement. Your standard industrial radios and phones provide zero traceability.

4. Full Orchestration Across Sites and Platforms

Walt unifies communication across multiple facilities, shifts, and departments. Walt provides enterprise-wide visibility while maintaining local operational control. No other solution can orchestrate manufacturing communication at this scale.

What This Means for Your Competitive Position

While your competitors continue operating with communication black holes, Walt gives you:

- Perfect incident reconstruction – Know exactly what happened, when, and why

- Predictive problem identification – Spot issues before they impact production

- Accelerated knowledge transfer – New hires access decades of tribal knowledge instantly

- True multi-site learning – Breakthrough discoveries spread across your entire network

- Forensic-level accountability – End the “he said, she said” of operational disputes

The Bottom Line: This Isn’t Just Better Communication — It’s Operational Intelligence

There are known unknowns, and there are unknown unknowns. But it doesn’t have to be this way.

The manufacturing operations iceberg is real, and traditional communication systems are built to ignore it or even neglect it. Push-to-talk radios, phone calls, and messaging apps create communication black holes where 70% of your operational intelligence disappears forever.

Walt by weavix is the only communication platform purpose-built to capture, preserve, and analyze the frontline intelligence that drives manufacturing excellence.

The companies that recognize this competitive advantage first will pull ahead of competitors who continue sailing blind with legacy communication systems.

Ready to discover what’s hidden beneath the surface of your operations?

Contact the Walt team to learn how you can transform your communication black holes into operational intelligence before your competitors figure out what they’re missing.

Don’t let the 70% you can’t see determine your success while competitors who can see everything leave you behind.

Schedule a demo today.

Frequently Asked Questions

What is an example of a traditional communication solution?

A common example of a traditional communication solution is PTT radios, still widely used in manufacturing facilities to connect workers across noisy environments. PTT radios offer instant voice communication but rely on real-time conversations without capturing or archiving data. This characteristic causes key information to vanish as soon as the conversation ends, leaving no record behind, leaving no permanent record or data to analyze later.

Cutting-edge platforms like Walt solve this problem by automatically transcribing and storing every message, creating a permanent record that turns frontline conversations into valuable operational intelligence.

Keep reading: Find out how Walt’s speech-to-text and text-to-speech functions boost communication efficiency

What are the most common types of traditional manufacturing communication systems?

Traditional manufacturing communication systems usually include:

- Analog or DMR radios that don’t record conversations or connect with other systems

- Landline phones for direct calls, but limited by fixed locations

- Basic messaging platforms like SMS or email

These tools handle direct conversations and quick updates, but don’t offer much beyond that. They lack features like transcription and real-time language translation, creating gaps where critical operational intelligence disappears. Walt stores every conversation in the cloud, making information accessible across languages and locations, so nothing important gets lost.

What is the difference between traditional and modern communication in manufacturing?

While traditional communication systems treat conversations as temporary and unrecorded, modern communication in manufacturing captures, transcribes, and enables conversations across languages and locations for lasting use. In other words, modern systems like Walt don’t just connect your workforce; they make their knowledge visible and valuable.

Keep reading: Bring communication to the forefront of your business with our connected worker platform

How do traditional manufacturing radio systems handle communication during emergencies?

Traditional manufacturing radios provide instant voice contact, which is critical during emergencies. However, these solutions leave no permanent record of what was said, when, or by whom. This makes it hard to verify information or investigate incidents afterward.

Plus, language barriers and multi-site coordination challenges can delay critical messages. Without features like automatic transcription or message playback, traditional radios often leave safety communication incomplete and untraceable.

What are the benefits of replacing traditional communication systems in manufacturing?

Replacing traditional communication systems with a frontline platform like Walt eliminates the blind spots that hide cascading failures and safety risks. Benefits include:

- Faster incident response: Our safety solutions help teams act quickly and accurately

- Global knowledge sharing: AI language translation helps spread ideas across sites and linguistic boundaries

- Stronger accountability: Timestamped records create a clear trail of decisions and actions

Improved safety and quality: Early warnings and our alerting system reduce risks and errors