Key Takeaways

- Duress alarms are safety devices that instantly alert responders when workers face emergencies through manual button presses or automatic detection.

- Manufacturing environments require specialized man-down detection systems that automatically monitor worker safety, unlike basic panic buttons designed for customer service settings.

- OSHA compliance often requires emergency communication systems for confined spaces, hazardous materials, and lone worker situations in industrial facilities.

- Modern duress alarm systems integrate with industrial communication platforms like smart radios, providing GPS location tracking and two-way emergency communication.

- Key difference: Panic buttons (manual) vs duress alarms (manual/automatic) vs man-down systems (automatic detection) – manufacturing facilities typically need automatic detection for lone workers and hazardous environments.

What is a Duress Alarm?

A duress alarm is a safety device that allows workers to instantly signal for help during emergencies by pressing a button or triggering an automatic alert. These systems are designed to provide rapid assistance when employees face dangerous situations, medical emergencies, or security threats in the workplace.

Unlike traditional communication devices, duress alarms prioritize immediate emergency response over regular communication, ensuring help arrives quickly when workers need it most.

How Duress Alarms Work

Duress alarms operate through a simple but effective process:

- Activation: Workers press an emergency button or the system automatically detects a problem (such as a worker falling down)

- Alert transmission: The system immediately sends notifications to designated responders with the worker’s location

- Response coordination: Emergency responders receive instant alerts and can communicate with the worker if needed

- Documentation: All emergency events are logged for safety analysis and compliance reporting

Modern duress alarm systems use wireless technology to ensure reliable communication even in challenging industrial environments.

Types of Duress and Lone Worker Alarms

Manufacturing, Industrial and Lone Worker Environments

Manufacturing facilities require specialized duress alarm systems designed for harsh environments and specific safety risks:

- Man-down detection systems: Automatically detect if a worker has fallen or become incapacitated [See real-world examples of how Man-Down systems protect workers in Manufacturing & Oil and Gas].

- Lone Worker Alarms: Essential for employees working in warehouses, maintenance areas, or remote locations, these systems function as a dedicated lone worker alarm, ensuring they are never truly alone.

- Hazardous area certified devices: Meet safety requirements for environments with explosive gases or dust

- Integration with existing safety systems: Connect with facility alarm systems and emergency response protocols

Hospitality and Service Industries

Hotels, restaurants, and retail environments typically use:

- Silent Alarms: In volatile situations, a silent alarm capability allows workers to summon help discreetly without alerting the aggressor.

- Mobile panic apps: Smartphone-based solutions for mobile employees

- Fixed panic buttons: Mounted near cash registers or reception areas

Healthcare Facilities

Medical facilities focus on:

- Patient monitoring systems: Alert staff when patients need immediate assistance

- Staff safety devices: Protect healthcare workers from aggressive patients or visitors

- Code-specific alerts: Different alert types for medical emergencies vs security threats

Duress Alarms vs Panic Buttons vs Man-Down Systems

While these terms are often used interchangeably, they serve different purposes:

| System Type | Primary Use | Activation Method | Best For |

|---|---|---|---|

| Panic Button | Personal safety threats | Manual button press | Customer-facing environments |

| Duress Alarm | General emergencies | Manual or automatic | Multi-purpose workplace safety |

| Man-Down System | Worker incapacitation | Automatic detection | Industrial/lone worker scenarios |

For manufacturing environments, man-down detection systems are often the most appropriate choice because they:

- Automatically detect when workers become incapacitated

- Work effectively for lone workers in remote areas

- Integrate with industrial communication systems

- Meet OSHA safety requirements for hazardous work environments

Understanding the technical difference is step one. To understand the operational impact on your workforce, read our guide on Why You Need a Man-Down System.

OSHA Requirements and Compliance

The Occupational Safety and Health Administration (OSHA) requires employers to provide safe working conditions, which may include emergency communication systems in certain situations:

- General duty clause: Employers must address recognized workplace hazards

- Confined space requirements: OSHA mandates communication systems for workers in confined spaces

- Lone worker protection: While not explicitly required, OSHA emphasizes the need for emergency communication when workers are isolated

- Hazardous material handling: Emergency alert systems are often required when working with dangerous chemicals

- OSHA 1910.165 (Employee Alarm Systems): Specifically, OSHA 1910.165 requires that employee alarm systems be distinctive and recognizable, providing warning for necessary emergency action.”

When Manufacturing Needs Duress Alarms

Manufacturing facilities should implement duress alarm systems when:

- Workers operate alone in remote areas of the facility

- Hazardous materials are present that could incapacitate workers

- Heavy machinery operations pose injury risks

- Confined spaces are part of regular work activities

- Night shifts have minimal staffing levels

- OSHA compliance requires emergency communication capabilities

Implementation Considerations for Industrial Environments

Technical Requirements

- Intrinsic safety certification for explosive environments (Class 1, Division 2)

- Durability standards to withstand industrial conditions

- Battery life sufficient for full work shifts

- Wireless duress system coverage: Unlike hardwired legacy buttons, a modern wireless duress system deploys rapidly without expensive cabling infrastructure

- Integration capability with existing safety and communication systems

System Features for Manufacturing

- GPS location tracking to pinpoint worker location during emergencies

- Two-way communication allowing responders to assess situation severity

- Multiple alert types for different emergency scenarios

- Integration with facility systems such as PA announcements or lockdown procedures

- Compliance reporting for OSHA documentation requirements

ROI and Safety Benefits

Manufacturing facilities implementing duress alarm systems typically experience:

- Reduced emergency response time from minutes to seconds

- Improved worker confidence leading to better safety compliance

- Lower insurance costs due to enhanced safety measures

- Regulatory compliance meeting OSHA and industry safety standards

- Incident documentation supporting safety investigations and improvements

Duress Alarms vs Traditional Communication

While standard two-way radios enable workplace communication, duress alarms provide critical advantages for emergency situations:

- Dedicated emergency channels that don’t compete with routine communication

- Automatic location detection eliminating the need for workers to communicate their position

- Silent alarm capabilities for security threats where verbal communication might escalate danger

- Integration with emergency response systems ensuring proper protocols are followed

Integration with Smart Radio Systems

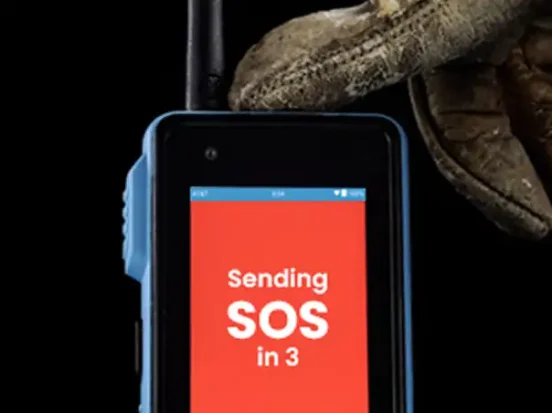

Modern industrial communication platforms like the Walt Smart Radio System combine routine communication with advanced safety features:

- Built-in man-down detection using accelerometer and motion sensors that automatically trigger alerts when workers fall or become motionless

- Real-Time Location System (RTLS): The Walt Smart Radio utilizes RTLS technology to pinpoint the exact coordinates of the distress signal, indoors or outdoors.

- System of record capabilities documenting all emergency events for compliance and safety analysis

- Seamless integration with existing facility safety systems and emergency protocols

The Walt system’s man-down feature activates automatically after detecting lack of movement for a configurable time period, ensuring lone workers receive immediate assistance even when unable to manually call for help. This integration ensures workers carry one device that handles both daily communication needs and emergency safety requirements.

Getting Started with Duress Alarm Systems

When implementing duress alarm systems in manufacturing environments:

- Assess workplace risks to determine appropriate system type

- Review OSHA requirements for your specific industry and processes

- Evaluate integration needs with existing safety and communication systems

- Consider worker mobility patterns to ensure adequate coverage

- Plan emergency response procedures that leverage the new technology

Conclusion

Duress alarms are essential safety devices that provide workers with immediate access to emergency assistance. For manufacturing and industrial environments, man-down detection systems offer the most comprehensive protection by automatically monitoring worker safety while integrating with broader facility safety protocols.

When selecting a duress alarm system, prioritize solutions designed for industrial environments that meet relevant safety certifications and integrate with your existing communication infrastructure. The investment in worker safety technology pays dividends through reduced incidents, improved compliance, and enhanced worker confidence.

About weavix: weavix manufactures the Walt Smart Radio System, providing industrial-grade communication and safety solutions for frontline workers in manufacturing, construction, and industrial environments. Learn more about our man-down detection capabilities and industrial communication solutions.