A Class 1 Div 2 location, as defined by the NEC, is an area where flammable gases or vapors are normally contained but may escape in ignitable amounts only during abnormal conditions such as leaks or equipment failure. These areas require certified equipment to prevent ignition

Unlike Class 1 Division 1 areas where hazardous materials are continuously present, Division 2 locations operate safely under normal conditions but require certified equipment and strict protocols to prevent ignition sources during unexpected releases.

This hazardous location is an area where flammable gases or vapors are normally confined within closed containers or systems but may become present in ignitable concentrations under abnormal conditions. These conditions include equipment failure, accidental container rupture, or ventilation system breakdown.

| Class | Division | Group |

|---|---|---|

| I – Flammable gases or vapors may be present | 1 – Ignitable concentrations of hazards exist under normal operation conditions and/or where the hazard is caused by frequent maintenance or repair work or frequent equipment failure 2 – Ignitable concentrations of hazards exist under abnormal operation conditions | Group A – Acetylene Group B – Hydrogen, butadiene, ethylene oxide, propylene oxide and acrolein Group C – Ethylene, cyclopropane and ethyl ether Group D – Acetone, ammonia, benzene, butane, ethanol, gasoline, hexane, methane, methanol, naphtha, natural gas, propane and toluene |

| II – Combustible dust may be present | 1 – Ignitable concentration of hazards exist under normal operation conditions and/or where the hazard is caused by frequent maintenance or repair work or frequent equipment failure 2 – Ignitable concentrations of hazards exist under abnormal operation conditions | Group E – Combustible metal dusts: aluminum, commercial alloys and magnesium Group F – Combustible carbonaceous dusts: carbon black, charcoal, coal and coke dusts Group G – Other combustible dusts: chemicals, flour, grain, plastic and wood |

| III – Easily ignitable fibers or flyings may be present | 1 – Ignitable concentration of hazards exist under normal operation conditions and/or where the hazard is caused by frequent maintenance or repair work or frequent equipment failure 2 – Ignitable concentrations of hazards exist under abnormal operation conditions | Not applicable |

NEC Definition

The Technical Definition

According to the National Electrical Code (NEC) Article 500, this hazardous location is defined as an area where:

- Volatile flammable liquids or gases are handled, processed, or used, but these substances are confined within closed containers or closed systems from which they can escape only during accidental rupture or breakdown of the container or system, or

- Ignitable concentrations of flammable gases or vapors are normally prevented by positive mechanical ventilation, but which might become hazardous through failure or abnormal operation of the ventilating equipment, or

- The location is adjacent to a Class 1 Division 1 area where ignitable concentrations of gases or vapors might occasionally be communicated, unless such communication is prevented by adequate positive-pressure ventilation from a source of clean air with effective safeguards against ventilation failure.

In Simpler Terms

Think of this area as a location where flammable materials are present but under control. The hazardous substances are safely contained in tanks, pipes, or sealed systems with proper ventilation keeping concentrations below dangerous levels.

The area only becomes hazardous when something goes wrong—a pipe breaks, a tank ruptures, or ventilation fails. This contrasts with Division 1 areas where hazardous materials are present during normal operations.

Common examples include:

- Storage rooms for sealed drums of flammable liquids

- Areas near loading docks where containers are transported but not opened

- Maintenance zones adjacent to processing areas

- Laboratory spaces with closed chemical storage systems

- Control rooms near refinery units with proper ventilation

Class 1 Division 1 vs Class 1 Div 2: Critical Differences

Understanding the distinction between Division 1 and Division 2 is essential for risk assessment, equipment selection, and regulatory compliance.

The Key Difference: Frequency of Hazardous Conditions

| Aspect | Class 1 Division 1 | Class 1 Division 2 |

|---|---|---|

| When hazardous materials are present | During normal operations, continuously or periodically | Only under abnormal conditions (equipment failure, accidents) |

| Concentration of flammable materials | Ignitable concentrations exist regularly | Below ignitable concentrations under normal conditions |

| Risk level | Highest risk. Constant hazard | Lower risk—controlled environment with contingency planning |

| Equipment requirements | Most stringent. Explosion-proof or intrinsically safe required | Less restrictive. Properly enclosed, non-incendive equipment allowed |

| Cost implications | Highest equipment costs ($1,200+ per device) | Moderate equipment costs (certified but less restrictive) |

| Typical operations | Active processing, tank filling, open containers | Sealed systems, storage areas, controlled environments |

Deep Dive: What is an Intrinically Safe Radio?

Real-World Examples

Class 1 Division 1 scenarios:

- Inside paint spray booths during operation

- Areas where fuel is transferred from one container to another

- Tank filling stations during active loading

- Open dip tanks containing flammable solvents

- Petroleum refinery process units during operation

Download infographic here.

Why the Division Matters for Your Facility

The classification directly impacts:

- Equipment costs: Division 1 requires more expensive certified equipment across all electrical and electronic devices

- Operational flexibility: Division 2 allows more standard equipment with proper certification, reducing costs

- Maintenance requirements: Division 1 areas require more frequent inspections and stricter protocols

- Insurance and liability: Proper classification affects your facility’s risk profile and insurance premiums

- Worker safety: Understanding which areas are which helps train workers on appropriate precautions

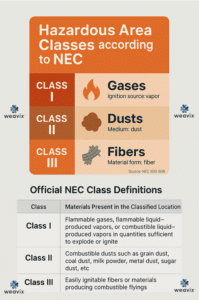

Complete NEC Hazardous Location Classification System

The National Electrical Code divides hazardous locations into three Classes based on the type of hazardous material present, then further subdivides each Class into two Divisions based on the likelihood of hazardous concentrations.

Understanding the Classification System

Classes define the TYPE of hazardous material:

- Class 1: Flammable gases and vapors

- Class 2: Combustible dusts

- Class 3: Easily ignitable fibers and flyings

Divisions define the FREQUENCY of hazardous concentrations:

- Division 1: Present under normal operations

- Division 2: Present only under abnormal conditions

Complete NEC Hazardous Area Classification Table

| Classification | Hazardous Material Type | When Present | Common Examples |

|---|---|---|---|

| Class 1 Division 1 | Flammable gases, vapors (acetylene, hydrogen, propane, gasoline vapor) | Continuously or periodically under normal conditions | Paint spray booths, fuel transfer areas, open process vessels, dip tanks with volatile solvents |

| Class 1 Division 2 | Flammable gases, vapors | Only under abnormal conditions (failures, accidents) | Sealed storage rooms, areas with ventilation systems, closed piping systems, control rooms near refineries |

| Class 2 Division 1 | Combustible dust (metal, coal, grain, plastic) | Sufficient quantities to produce explosive mixtures under normal operations | Grain elevators during operation, coal pulverizing plants, metal powder manufacturing areas |

| Class 2 Division 2 | Combustible dust | Not normally in suspension; accumulations prevent ignitable concentrations | Storage areas for bagged materials, enclosed conveyor systems, areas near Division 1 with barriers |

| Class 3 Division 1 | Easily ignitable fibers, flyings (cotton, wood, textile) | Materials handled, manufactured, or used in quantities that produce ignitable fibers | Textile mills, woodworking plants, cotton processing facilities during operation |

| Class 3 Division 2 | Easily ignitable fibers, flyings | Materials stored or handled, but not in process form | Fiber storage warehouses, lumber storage, textile storage areas |

Groups Within Class 1 Locations

Class 1 locations are further divided into Groups (A, B, C, D) based on the specific gas or vapor properties:

| Group | Representative Gas | Ignition Energy | Common Applications |

|---|---|---|---|

| Group A | Acetylene | Extremely low (most hazardous) | Welding operations, chemical synthesis |

| Group B | Hydrogen, manufactured gas | Very low | Hydrogen production, battery charging rooms |

| Group C | Ethylene, cyclopropane | Low | Chemical plants, plastics manufacturing |

| Group D | Propane, gasoline, natural gas, butane | Moderate (least hazardous of Class 1) | Gas stations, refineries, oil & gas facilities |

Temperature Classifications (T-Codes)

Equipment must also have a temperature rating to ensure its surface doesn’t exceed the ignition temperature of materials present:

| T-Code | Maximum Surface Temperature | Suitable For |

|---|---|---|

| T1 | 450°C (842°F) | Most common gases and vapors |

| T2 | 300°C (572°F) | Standard applications |

| T3 | 200°C (392°F) | More sensitive materials |

| T4 | 135°C (275°F) | Materials like acetaldehyde |

| T5 | 100°C (212°F) | Low ignition point materials |

| T6 | 85°C (185°F) | Carbon disulfide and other extremely sen |

Example: Equipment marked “Class 1, Division 2, Group D, T4” can be safely used in a Division 2 location with Group D gases where surface temperatures won’t exceed 135°C.

Class 1 Div 2 Requirements: What You Need to Know

Operating safely in this hazardous location requires compliance with specific NEC requirements. These standards exist to prevent equipment from becoming an ignition source during normal operation or in the event of abnormal conditions.

Equipment Certification Requirements

All electrical and electronic equipment used in C1D2 areas must be:

- Properly certified for the specific classification

- Must be listed by a recognized testing laboratory (UL, CSA, FM Global, IECEx)

- Certification must match or exceed the area classification

- Equipment certified for Division 1 can be used in Division 2, but not vice versa

- Marked with appropriate ratings

- Class, Division, and Group designation

- Temperature code (T-code)

- Certification body identifier

- Suitable for the protection technique employed:

- Non-incendive: Incapable of releasing sufficient energy under normal or abnormal conditions

- Hermetically sealed: Sealed devices preventing external atmosphere entry

- Purged and pressurized: Maintains internal pressure preventing hazardous gas entry

- Intrinsically safe: Circuits that cannot release ignition energy (most common for instrumentation)

- Explosion-proof (from Division 1): Contains explosions within the enclosure

Ventilation System Requirements

these areas typically rely on mechanical ventilation to maintain safety:

- Adequate air changes per hour based on the specific gases present and facility size

- Continuous operation with interlocks preventing equipment operation if ventilation fails

- Monitoring systems with alarms to alert operators of ventilation system failures

- Backup systems or automatic shutdown procedures if primary ventilation is lost

- Fresh air supply from safe areas to ensure no contamination of ventilation air

Installation and Maintenance Standards

Beyond equipment selection, proper installation and ongoing maintenance are critical:

Installation requirements:

- Proper grounding and bonding of all equipment

- Sealed conduit fittings to prevent gas migration

- Appropriate separation distances from Division 1 areas

- Compliance with wiring methods specified in NEC Article 501

Maintenance requirements:

- Regular inspection of equipment integrity and certification labels

- Testing of ventilation systems and alarms

- Documentation of all maintenance activities

- Replacement of damaged equipment with properly rated substitutes

- Periodic area classification reviews to ensure classifications remain accurate

Worker Training Requirements

OSHA and industry best practices require comprehensive training for personnel working in Class 1 Div 2 areas:

- Understanding of hazardous area classifications and what they mean

- Recognition of equipment certification markings

- Proper use of certified equipment (especially communication devices)

- Emergency response procedures for ventilation failure or gas release

- Hot work permit procedures if any maintenance requires potential ignition sources

- Awareness of changing conditions that could elevate risk levels

Documentation and Compliance

Facilities must maintain:

- Area classification drawings showing all classified areas and their boundaries

- Equipment inventory with certification documentation

- Maintenance records demonstrating ongoing compliance

- Training records for all personnel working in classified areas

- Inspection reports from regular safety audits

Failure to meet these requirements can result in OSHA citations, increased insurance premiums, and most importantly, serious safety incidents.

Industries with C1 Division 2 Hazardous Locations

C1 Division 2 classifications appear across numerous industries where flammable gases and vapors are handled but kept under control. Understanding whether your industry typically includes these areas helps with proper planning and compliance.

Oil & Gas Industry

Common Class 1 Div 2 areas:

- Control rooms and instrument buildings near process units

- Motor control centers with proper ventilation

- Loading rack control stations

- Maintenance shops adjacent to refinery units

- Laboratory spaces with enclosed chemical analysis equipment

- Compressor buildings with ventilation systems

Typical materials present: Natural gas, propane, butane, gasoline vapors, hydrogen sulfide

Chemical Manufacturing

Common Class 1 Div 2 areas:

- Chemical storage warehouses with sealed drums

- Quality control laboratories

- Packaging areas for sealed containers

- Raw material receiving areas

- Control rooms near reactors

- Maintenance corridors with proper barriers

Typical materials present: Solvents, acetone, ethanol, toluene, benzene, various chemical vapors

Paint and Coating Facilities

Common Class 1 Div 2 areas:

- Paint storage rooms with closed containers

- Mixing rooms with local exhaust ventilation

- Can filling areas (when not actively filling)

- Warehouse storage for sealed products

- Quality testing labs

Typical materials present: Paint thinners, MEK, acetone, xylene, various VOCs

Pharmaceutical Manufacturing

Common Class 1 Div 2 areas:

- Solvent storage areas

- Equipment cleaning rooms

- Alcohol-based product storage

- Extraction areas with closed systems

- Analytical laboratories

Typical materials present: Ethanol, isopropanol, methanol, acetone

Food and Beverage Processing

Common Class 1 Div 2 areas:

- Ethanol storage for extraction processes

- Fermentation areas with controlled ventilation

- Flavor and extract production zones

- Cleaning solution storage areas

Typical materials present: Ethanol, natural gas for heating systems

Automotive and Aerospace

Common Class 1 Div 2 areas:

- Parts cleaning stations with sealed equipment

- Paint storage and preparation areas

- Fuel system testing areas

- Solvent storage rooms

- Composite manufacturing areas using resins

Typical materials present: Gasoline, jet fuel vapors, acetone, MEK, various solvents

Wastewater Treatment Plants

Common Class 1 Div 2 areas:

- Digester control buildings

- Pump stations with proper ventilation

- Gas handling equipment rooms

- Areas adjacent to anaerobic digesters

Typical materials present: Methane, hydrogen sulfide

Does Your Facility Need C1 Div-2 Equipment?

If your facility stores, handles, or processes any flammable liquids or gases—even in sealed containers—you likely have C1D2 areas. A professional hazardous area classification study can:

- Identify all classified locations in your facility

- Determine appropriate Class, Division, and Group designations

- Establish boundaries for each hazardous area

- Specify equipment requirements for each zone

- Ensure compliance with NEC and OSHA regulations

Working without proper classification puts workers at risk and exposes your organization to regulatory penalties.

C1D2 Certified Communication Devices

One of the most challenging aspects of operating in these environments is maintaining effective worker communication while ensuring all devices meet safety requirements.

The Communication Challenge in Hazardous Areas

Workers in these locations need reliable communication for:

- Coordinating operations across different zones

- Emergency response and evacuation procedures

- Maintenance and troubleshooting support

- Daily operational check-ins and status updates

- Reporting abnormal conditions immediately

However, traditional communication devices pose significant challenges in these environments.

Why Standard Smartphones Don’t Work

Most smartphones are NOT certified for use because they:

- Generate heat that could exceed temperature classification limits

- Have batteries that can fail and create sparks

- Contain circuits capable of releasing ignition energy

- Lack proper enclosures to contain potential ignition sources

- Cannot be repaired or modified without voiding any safety characteristics

Even smartphones marketed as “intrinsically safe” often come with severe limitations:

- Restrictions on which features can be used in hazardous areas

- Complex mode-switching requirements

- Limited functionality when in “safe” mode

- Risk of user error activating unsafe features

- High costs (often $800-$1,500 per device)

Traditional Two-Way Radios: The Cost Barrier

Legacy two-way radios with this certification are available but present financial challenges:

Typical costs:

- Basic Class 1 Div 2 two-way radios: $800-$1,200+ per unit

- Radio infrastructure (repeaters, base stations): $10,000-$50,000+

- Ongoing licensing and maintenance costs

- Limited to voice communication only—no digital collaboration

For facilities needing to equip entire workforces (50-500+ workers), these costs become prohibitive, forcing difficult choices between worker connectivity and budget constraints.

Walt Smart Radio: Full-Featured Communication

Our Walt Smart Radio is globally certified as an intrinsically safe device, meaning workers can safely use ALL available features of the device while operating in Div-2 hazardous locations or any lower classification (Class 2, Class 3, or non-hazardous areas).

Key advantages:

Complete certification with no restrictions:

- Full device functionality available in Class 1 Div 2 environments

- No need to switch modes or disable features

- Voice, text, images, and digital collaboration all certified

- Reduces user error risk from complex safety protocols

Cost-effective deployment:

- Significantly lower per-unit cost than traditional certified radios

- No expensive radio infrastructure required

- Scales easily across entire workforces

- Predictable subscription pricing

Modern digital capabilities:

- Push-to-talk voice communication

- Text messaging and group chats

- Photo and document sharing

- Location tracking (where permitted)

- Integration with existing communication systems

- Cloud-based management and updates

Important limitation: Walt Smart Radio is NOT certified for Class 1 Division 1 environments. For Division 1 areas, workers must use equipment with higher protection levels or follow hot work permit procedures.

Equipment Hierarchy: What Works Where

Understanding which devices can be used in which classifications:

| Device Type | Class 1 Div 1 | Class 1 Div 2 | Class 2 | Class 3 | Non-Hazardous |

|---|---|---|---|---|---|

| Division 1 certified radios | ✓ | ✓ | ✓ | ✓ | ✓ |

| Walt Smart Radio | ✗ | ✓ | ✓ | ✓ | ✓ |

| Standard two-way radios | ✗ | ✗ | ✗ | ✗ | ✓ |

| Regular smartphones | ✗ | ✗ | ✗ | ✗ | ✓ |

Remember: Equipment certified for a more hazardous classification can always be used in less hazardous areas, but never the reverse.

Making the Right Choice for Your Facility

When selecting communication devices for C1D2 areas, consider:

- What classifications exist in your facility? If you only have Div 2 and lower, you have more cost-effective options

- How many workers need devices? Cost-per-unit matters more with larger deployments

- What communication features do you need? Voice-only vs. full digital collaboration

- What’s your infrastructure budget? Traditional radio systems require significant upfront investment

- How important is user adoption? Intuitive devices reduce training time and usage errors

Scenarios:

- Storage rooms with sealed drums of flammable liquids

- Areas adjacent to Division 1 locations with proper ventilation

- Closed piping systems containing flammable gases

- Equipment rooms with mechanical ventilation systems

- Loading docks where sealed containers are moved but not opened

Class 1 Div.2 Hazardous Locations

Class 1 identifies hazardous locations where flammable gases or vapors may be present in the air under normal conditions at any time. Any location with this Class 1 hazardous location label distinguishes that those products are present and extra precautions should be taken while in or around the area.

There are two Divisions under the Class 1 classification: Class 1 Div. 1 and Class 1 Div. 2. Regarding hazardous locations, the distinction between the two is if the concentration of the flammable gases and vapors identified in its Class 1 designation is ignitable under normal working conditions or under abnormal working conditions.

If the concentration is enough to ignite under normal conditions, it’s a Class 1 Div. 1 area. If the concentration is enough to ignite under unusual conditions in the area, it’s labeled as Class 1 Div. 2.

A class 1 div 2 hazardous location handles, processes, or uses flammable gases or vapors while meeting strict class 1 div 2 requirements, but they are kept safely confined in designated areas and containers. These areas also have specialized ventilation to keep these products from concentrating enough to become ignitable mixtures. However, under abnormal conditions, such as a container being damaged, the product can escape and ignite.

Regarding a Class 1 Div. 1 hazardous environment, additional precautions are taken to keep workers safe while inside these areas.

Why the Division Matters for Your Facility

The classification directly impacts:

- Equipment costs: Division 1 requires more expensive certified equipment across all electrical and electronic devices

- Operational flexibility: Division 2 allows more standard equipment with proper certification, reducing costs

- Maintenance requirements: Division 1 areas require more frequent inspections and stricter protocols

- Insurance and liability: Proper classification affects your facility’s risk profile and insurance premiums

- Worker safety: Understanding which areas are which helps train workers on appropriate precautions

A Class 1 Div. 2 Smart Radio for Flammable Gases

These designations don’t only apply to locations workers operate in, but the tools they are allowed to use while inside these areas. Every device approved for these designations is also approved for the hazardous areas beneath it.

For example, our Walt Smart Radio is Class 1 Div. 2 certified. While you can’t safely use it in a Class 1 Div. 1 area, you can for a Class 1 Div. 2 workplace, plus any Class 2 and Class 3 environment.

Many legacy radios also reach this designation, however, the price per radio gradually increases with its higher certification. With some radios priced at over $1,200 due to the certification, this financial barrier keeps facilities from equipping their whole workforce.

On the other hand, smartphones typically do not receive a Class 1 Div. 2 classification level. If they do, there are a number of warnings and safety implications to consider before operating in a hazardous area.

With this distinction, Walt Smart Radio is globally certified to safely operate in these areas in its entirety while under normal operating conditions. Users can safely access and use the full digital collaboration capabilities of the platform while in these areas as well.

Class 1 Div 1 vs Class 1 Div 2: Key Differences

Understanding the difference between Class 1 Div 1 and Class 1 Div 2 is essential for workplace safety. The key distinction lies in when flammable gases or vapors are present at ignitable concentrations.

Class 1 Div 1 vs Div 2 comparison:

- C1 – Division 1: Flammable gases or vapors are present at ignitable concentrations under normal operating conditions. This represents the highest risk level and requires the most stringent safety measures.

- C1 – Division 2: Flammable gases or vapors are typically confined and only present at ignitable concentrations under abnormal conditions, such as equipment failure or container damage. When comparing Class 1 Div 1 vs Class 1 Div 2 environments, the Division 2 classification allows for more operational flexibility while still maintaining strict safety standards. This is why many industrial facilities operate under class 1 div 2 guidelines, where proper containment and ventilation systems keep hazardous materials under control.

Requirements

To operate safely in a div2 hazardous location, equipment must meet specific class 1 div 2 requirements established by the National Electrical Code (NEC).

Key Class 1 Div 2 requirements include:

- Equipment Certification: All electrical devices must be certified for use in class 1 div 2 hazardous locations. This certification ensures the equipment won’t become an ignition source under normal or abnormal conditions.

- Proper Enclosures: Devices must have appropriate enclosures that prevent sparks or hot surfaces from igniting flammable atmospheres.

- Temperature Ratings: Equipment surface temperatures must remain below the ignition temperature of hazardous substances present in the area.

- Ventilation Systems: NEC Class 1 div 2 electrical requirements in hazardous locations must have adequate ventilation to prevent the accumulation of flammable gases or vapors.

- Worker Training: Personnel must be trained on the specific requirements for their workplace and the proper use of certified equipment.

Frequently Asked Questions

What is C1D2?

This class refers to hazardous locations where flammable gases or vapors are present but normally confined in closed containers or systems. Under normal conditions, these substances are not present in quantities sufficient to create an explosive atmosphere. The area only becomes hazardous during abnormal conditions such as equipment failure, container rupture, or ventilation system breakdown.

What is a C1 div 2 hazardous location?

This specific class of hazardous location is an area where flammable gases or vapors may be present only under abnormal conditions, such as equipment failure, container rupture, or system breakdown. These locations require certified equipment to prevent ignition sources but operate safely under normal conditions due to proper containment and ventilation systems. Examples include sealed chemical storage rooms, control rooms near refineries, and areas with closed piping systems.

How does This differ from Class 1 Division 1?

The primary difference between Class 1 Division 1 and Division 2 is the frequency and concentration of flammable materials:

- Division 1: Hazardous concentrations are present during normal operations, continuously or periodically

- Division 2: Hazardous concentrations only occur under abnormal conditions like equipment failures

This distinction affects equipment requirements, costs, and operational procedures. Division 1 requires more stringent and expensive protection measures, while Division 2 allows more flexibility with proper containment and ventilation.

What equipment can be used in these areas?

Equipment used in these areas must be:

- Certified by a recognized testing laboratory (UL, CSA, FM Global, IECEx)

- Rated for the specific Class, Division, and Group present

- Marked with appropriate temperature classification (T-code)

- Protected using approved methods: non-incendive, hermetically sealed, purged/pressurized, intrinsically safe, or explosion-proof

Equipment certified for Division 1 can be used in Division 2 locations, but Division 2 equipment cannot be used in Division 1 areas.

Does this class require explosion-proof equipment?

This hazardous zone NOT always require explosion-proof equipment. “Explosion-proof” is just one protection method suitable for these areas. Division 2 locations can also use:

- Non-incendive equipment (most common for Div 2)

- Hermetically sealed devices

- Purged and pressurized enclosures

- Intrinsically safe circuits

Explosion-proof equipment (required for Division 1) can be used in Division 2 but is typically more expensive than necessary.

What is the difference between NEC and IEC classification systems?

The NEC (National Electrical Code) system, used primarily in the United States, uses Classes and Divisions:

- Class 1, Division 1 or Division 2 (gases/vapors)

- Class 2, Division 1 or Division 2 (dusts)

- Class 3, Division 1 or Division 2 (fibers)

The IEC (International Electrotechnical Commission) system, used globally, uses Zones:

- Zone 0, 1, or 2 (gases/vapors)

- Zone 20, 21, or 22 (dusts)

Approximate equivalents:

- Division 1 ≈ Zone 1

- Division 2 ≈ Zone 2

- No NEC equivalent for Zone 0 (most hazardous)

What are Groups in Class 1 hazardous locations?

Groups classify gases and vapors by their ignition properties within Class 1 locations:

- Group A: Acetylene (most hazardous, lowest ignition energy)

- Group B: Hydrogen, manufactured gas

- Group C: Ethylene, cyclopropane

- Group D: Propane, gasoline, natural gas, butane (least hazardous of Class 1)

Equipment must be rated for the specific Group(s) present in your facility.

What do temperature classifications (T-codes) mean?

T-codes indicate the maximum surface temperature equipment can reach, which must be below the ignition temperature of materials present:

- T1: 450°C (842°F) – Most gases

- T2: 300°C (572°F) – Standard applications

- T3: 200°C (392°F) – More sensitive materials

- T4: 135°C (275°F) – Acetaldehyde

- T5: 100°C (212°F) – Low ignition materials

- T6: 85°C (185°F) – Carbon disulfide (most restrictive)

Equipment marked T4 can operate in any area requiring T4, T3, T2, or T1, but cannot be used where T5 or T6 is required.

Can smartphones be used in this hazardous areas?

Standard smartphones are NOT certified for use in this area and pose serious safety risks. Some specially designed “intrinsically safe” smartphones exist but typically have significant limitations:

- Restricted features in hazardous mode

- Complex switching procedures

- High costs ($800-$1,500+)

- Risk of user error

Purpose-built certified devices like industrial two-way radios or certified smart radios are recommended for reliable, compliant communication in these environments.

How do you determine if an area is this hazardous location?

Determining area classification requires a formal hazardous area classification study conducted by qualified professionals. The process includes:

- Material assessment: Identify all flammable gases and vapors present

- Source identification: Locate all potential release points

- Release probability analysis: Determine if releases occur during normal or only abnormal conditions

- Ventilation evaluation: Assess adequacy of mechanical or natural ventilation

- Extent calculation: Calculate the distance hazardous concentrations could travel

- Documentation: Create area classification drawings showing all boundaries

This study should be updated whenever processes change, new equipment is installed, or materials are modified.

What is the penalty for non-compliance with hazardous area requirements?

OSHA can issue citations for non-compliance with hazardous location requirements under the General Duty Clause and specific standards. Penalties include:

- Serious violations: Up to $16,131 per violation

- Willful or repeated violations: Up to $161,323 per violation

- Failure to abate: Up to $16,131 per day beyond the abatement date

Beyond financial penalties, non-compliance can result in:

- Increased insurance premiums or loss of coverage

- Facility shutdown orders

- Civil liability from worker injuries

- Criminal charges if negligence leads to fatalities

Most importantly, non-compliance puts workers’ lives at risk.

Do I need a hot work permit in this hazardous zone?

Yes, hot work (welding, cutting, grinding, or any operation that could produce sparks or flames) in these areas requires a hot work permit. The permit process includes:

- Gas testing to confirm the area is free of flammable concentrations

- Implementation of fire watches

- Availability of fire suppression equipment

- Clearance from a qualified person

- Continuous monitoring during hot work

- Post-work inspection

International Classification: Zone System vs Division System

While this guide focuses on the NEC Class and Division system used in the United States, it’s valuable to understand the international Zone system for global operations or equipment sourcing.

IEC Zone Classification System

The International Electrotechnical Commission (IEC) system uses Zones instead of Divisions:

For gases and vapors:

- Zone 0: Explosive atmosphere present continuously or for long periods (most hazardous)

- Zone 1: Explosive atmosphere likely to occur in normal operation periodically

- Zone 2: Explosive atmosphere not likely to occur, or only for short periods

For combustible dusts:

- Zone 20: Combustible dust cloud present continuously or for long periods

- Zone 21: Combustible dust cloud likely to occur periodically

- Zone 22: Combustible dust cloud not likely to occur or only briefly

Approximate Equivalencies

While not perfect matches, general equivalencies help understand both systems:

| NEC System | IEC Zone System | Risk Level |

|---|---|---|

| No equivalent | Zone 0 | Highest (continuous presence) |

| Class 1 Division 1 | Zone 1 | High (normal operations) |

| Class 1 Division 2 | Zone 2 | Moderate (abnormal c |

| No equivalent | Zone 20 | Highest (continuous dust cloud) |

| Class 2 Division 1 | Zone 21 | High (normal operations) |

| Class 2 Division 2 | Zone 22 | Moderate (abnormal conditions) |

Equipment Protection Levels (EPL)

The IEC system also uses Equipment Protection Levels:

- EPL Ga: Very high protection (Zone 0 suitable)

- EPL Gb: High protection (Zone 1 suitable)

- EPL Gc: Enhanced protection (Zone 2 suitable)

For dusts:

- EPL Da: Very high protection (Zone 20)

- EPL Db: High protection (Zone 21)

- EPL Dc: Enhanced protection (Zone 22)

Why Understanding Both Systems Matters

Global equipment sourcing: Many manufacturers produce equipment certified to IEC standards. Understanding equivalencies helps evaluate if international equipment meets your NEC requirements.

International facilities: Companies with operations in multiple countries need to comply with local standards. Understanding both systems facilitates consistent safety practices globally.

Harmonization trend: The US is gradually moving toward greater alignment with IEC standards. The NEC increasingly references IEC protection methods and terminology.

Equipment markings: You may encounter equipment marked with both systems (e.g., “Class I, Division 2, Groups C, D / Zone 2, IIC”).

Taking Action: Next Steps for Your Facility

Assess Your Current Situation

If you operate a facility that handles, stores, or processes flammable materials, take these steps:

- Conduct or update your hazardous area classification study

- Required every 3-5 years or when processes change

- Must be performed by qualified professionals

- Creates the foundation for all other safety measures

- Inventory all equipment in classified areas

- Document certification markings

- Verify equipment matches area classification requirements

- Identify any non-compliant equipment requiring replacement

- Review ventilation systems

- Ensure adequate capacity for current operations

- Test monitoring and alarm systems

- Verify interlocks function properly

- Audit worker training

- Confirm all personnel understand hazardous area basics

- Verify workers can identify classification markings

- Test emergency response knowledge

- Evaluate communication capabilities

- Assess how workers currently communicate in classified areas

- Identify gaps in coverage or connectivity

- Consider upgrading to certified modern communication devices

Ensuring Worker Safety and Compliance

Proper management of this hazardous location requires ongoing attention:

Engineering controls:

- Maintain containment systems to prevent releases

- Keep ventilation systems operating effectively

- Use properly certified equipment throughout

Administrative controls:

- Implement hot work permit systems

- Establish maintenance procedures for classified areas

- Maintain current area classification drawings

- Document all equipment certifications

Personal protective equipment:

- Provide appropriate PPE for potential exposures

- Ensure workers understand when and how to use PPE

- Maintain and inspect PPE regularly

Continuous improvement:

- Review incidents and near-misses

- Update procedures based on lessons learned

- Stay current with code updates and industry best practices

Get Certified Communication for Your C1 div 2 Workers

If you have workers routinely operating in these NEC hazardous locations and need a modern, cost-effective way for them to safely communicate, the Walt Smart Radio provides full-featured digital collaboration capabilities with complete Class 1 Div 2 certification.

Schedule a demo to see how Walt Smart Radio can:

- Keep your workforce connected safely and compliantly

- Reduce communication equipment costs compared to legacy alternatives

- Provide modern digital capabilities beyond voice-only communication

- Scale easily across your entire operation

Schedule a demo of Walt Smart Radio today.

Additional Resources

Standards and Codes:

- NFPA 70: National Electrical Code (NEC)

- API RP 505: Recommended Practice for Classification of Locations for Electrical Installations at Petroleum Facilities

- IEC 60079 series: Explosive atmospheres standards

Regulatory Agencies:

- OSHA: Occupational Safety and Health Administration

- NFPA: National Fire Protection Association

- API: American Petroleum Institute

Training and Certification:

- Hazardous area classification training courses

- Equipment installation and maintenance certifications

- Worker safety training programs

Understanding hazardous locations is essential for maintaining safe operations in industries handling flammable materials. Proper classification, equipment selection, and worker training create layers of protection that prevent incidents and ensure regulatory compliance.

Never perform hot work in hazardous areas without proper authorization and safety measures.

Last updated: October 10, 2025

The Technical Definition

According to the National Electrical Code (NEC) Article 500, the designation is defined as an area where:

- Volatile flammable liquids or gases are handled, processed, or used, but these substances are confined within closed containers or closed systems from which they can escape only during accidental rupture or breakdown of the container or system, or

- Ignitable concentrations of flammable gases or vapors are normally prevented by positive mechanical ventilation, but which might become hazardous through failure or abnormal operation of the ventilating equipment, or

- The location is adjacent to a Class 1 Division 1 area where ignitable concentrations of gases or vapors might occasionally be communicated, unless such communication is prevented by adequate positive-pressure ventilation from a source of clean air with effective safeguards against ventilation failure.

In Simpler Terms

Think of this designation as a location where flammable materials are present but under control. The hazardous substances are safely contained in tanks, pipes, or sealed systems with proper ventilation keeping concentrations below dangerous levels.

The area only becomes hazardous when something goes wrong—a pipe breaks, a tank ruptures, or ventilation fails. This contrasts with Division 1 areas where hazardous materials are present during normal operations.

Common examples include:

- Storage rooms for sealed drums of flammable liquids

- Areas near loading docks where containers are transported but not opened

- Maintenance zones adjacent to processing areas

- Laboratory spaces with closed chemical storage systems

- Control rooms near refinery units with proper ventilation

Class 1 Division 1 vs Division 2: Critical Differences

Understanding the distinction between Division 1 and Division 2 is essential for risk assessment, equipment selection, and regulatory compliance.

The Key Difference: Frequency of Hazardous Conditions

| Aspect | Class 1 Division 1 | Class 1 Division 2 |

|---|---|---|

| When hazardous materials are present | During normal operations, continuously or periodically | Only under abnormal conditions (equipment failure, accidents) |

| Concentration of flammable materials | Ignitable concentrations exist regularly | Below ignitable concentrations under normal conditions |

| Risk level | Highest risk. Constant hazard | Lower risk—controlled environment with contingency planning |

| Equipment requirements | Most stringent. Explosion-proof or intrinsically safe required | Less restrictive. Properly enclosed, non-incendive equipment allowed |

| Cost implications | Highest equipment costs ($1,200+ per device) | Moderate equipment costs (certified but less restrictive) |

| Typical operations | Active processing, tank filling, open containers | Sealed systems, storage areas, controlled environments |

Real-World Examples

Class 1 Division 1 scenarios:

- Inside paint spray booths during operation

- Areas where fuel is transferred from one container to another

- Tank filling stations during active loading

- Open dip tanks containing flammable solvents

- Petroleum refinery process units during operation

Download infographic here.

Why the Division Matters for Your Facility

The classification directly impacts:

- Equipment costs: Division 1 requires more expensive certified equipment across all electrical and electronic devices

- Operational flexibility: Division 2 allows more standard equipment with proper certification, reducing costs

- Maintenance requirements: Division 1 areas require more frequent inspections and stricter protocols

- Insurance and liability: Proper classification affects your facility’s risk profile and insurance premiums

- Worker safety: Understanding which areas are which helps train workers on appropriate precautions

Complete NEC Hazardous Location Classification System

The National Electrical Code divides hazardous locations into three Classes based on the type of hazardous material present, then further subdivides each Class into two Divisions based on the likelihood of hazardous concentrations.

Understanding the Classification System

Classes define the TYPE of hazardous material:

- Class 1: Flammable gases and vapors

- Class 2: Combustible dusts

- Class 3: Easily ignitable fibers and flyings

Divisions define the FREQUENCY of hazardous concentrations:

- Division 1: Present under normal operations

- Division 2: Present only under abnormal conditions

Complete NEC Hazardous Area Classification Table

| Classification | Hazardous Material Type | When Present | Common Examples |

|---|---|---|---|

| Class 1 Division 1 | Flammable gases, vapors (acetylene, hydrogen, propane, gasoline vapor) | Continuously or periodically under normal conditions | Paint spray booths, fuel transfer areas, open process vessels, dip tanks with volatile solvents |

| Class 1 Division 2 | Flammable gases, vapors | Only under abnormal conditions (failures, accidents) | Sealed storage rooms, areas with ventilation systems, closed piping systems, control rooms near refineries |

| Class 2 Division 1 | Combustible dust (metal, coal, grain, plastic) | Sufficient quantities to produce explosive mixtures under normal operations | Grain elevators during operation, coal pulverizing plants, metal powder manufacturing areas |

| Class 2 Division 2 | Combustible dust | Not normally in suspension; accumulations prevent ignitable concentrations | Storage areas for bagged materials, enclosed conveyor systems, areas near Division 1 with barriers |

| Class 3 Division 1 | Easily ignitable fibers, flyings (cotton, wood, textile) | Materials handled, manufactured, or used in quantities that produce ignitable fibers | Textile mills, woodworking plants, cotton processing facilities during operation |

| Class 3 Division 2 | Easily ignitable fibers, flyings | Materials stored or handled, but not in process form | Fiber storage warehouses, lumber storage, textile storage areas |

Groups Within Class 1 Locations

Class 1 locations are further divided into Groups (A, B, C, D) based on the specific gas or vapor properties:

| Group | Representative Gas | Ignition Energy | Common Applications |

|---|---|---|---|

| Group A | Acetylene | Extremely low (most hazardous) | Welding operations, chemical synthesis |

| Group B | Hydrogen, manufactured gas | Very low | Hydrogen production, battery charging rooms |

| Group C | Ethylene, cyclopropane | Low | Chemical plants, plastics manufacturing |

| Group D | Propane, gasoline, natural gas, butane | Moderate (least hazardous of Class 1) | Gas stations, refineries, oil & gas facilities |

Temperature Classifications (T-Codes)

Equipment must also have a temperature rating to ensure its surface doesn’t exceed the ignition temperature of materials present:

| T-Code | Maximum Surface Temperature | Suitable For |

|---|---|---|

| T1 | 450°C (842°F) | Most common gases and vapors |

| T2 | 300°C (572°F) | Standard applications |

| T3 | 200°C (392°F) | More sensitive materials |

| T4 | 135°C (275°F) | Materials like acetaldehyde |

| T5 | 100°C (212°F) | Low ignition point materials |

| T6 | 85°C (185°F) | Carbon disulfide and other extremely sen |

Example: Equipment marked “Class 1, Division 2, Group D, T4” can be safely used in a Division 2 location with Group D gases where surface temperatures won’t exceed 135°C.

C1-Div2 Requirements: What You Need to Know

Operating safely in these designated hazardous location requires compliance with specific NEC requirements. These standards exist to prevent equipment from becoming an ignition source during normal operation or in the event of abnormal conditions.

Equipment Certification Requirements

All electrical and electronic equipment used in these areas must be:

- Properly certified for the specific classification

- Must be listed by a recognized testing laboratory (UL, CSA, FM Global, IECEx)

- Certification must match or exceed the area classification

- Equipment certified for Division 1 can be used in Division 2, but not vice versa

- Marked with appropriate ratings

- Class, Division, and Group designation

- Temperature code (T-code)

- Certification body identifier

- Suitable for the protection technique employed:

- Non-incendive: Incapable of releasing sufficient energy under normal or abnormal conditions

- Hermetically sealed: Sealed devices preventing external atmosphere entry

- Purged and pressurized: Maintains internal pressure preventing hazardous gas entry

- Intrinsically safe: Circuits that cannot release ignition energy (most common for instrumentation)

- Explosion-proof (from Division 1): Contains explosions within the enclosure

Ventilation System Requirements

C1D2 areas typically rely on mechanical ventilation to maintain safety:

- Adequate air changes per hour based on the specific gases present and facility size

- Continuous operation with interlocks preventing equipment operation if ventilation fails

- Monitoring systems with alarms to alert operators of ventilation system failures

- Backup systems or automatic shutdown procedures if primary ventilation is lost

- Fresh air supply from safe areas to ensure no contamination of ventilation air

Installation and Maintenance Standards

Beyond equipment selection, proper installation and ongoing maintenance are critical:

Installation requirements:

- Proper grounding and bonding of all equipment

- Sealed conduit fittings to prevent gas migration

- Appropriate separation distances from Division 1 areas

- Compliance with wiring methods specified in NEC Article 501

Maintenance requirements:

- Regular inspection of equipment integrity and certification labels

- Testing of ventilation systems and alarms

- Documentation of all maintenance activities

- Replacement of damaged equipment with properly rated substitutes

- Periodic area classification reviews to ensure classifications remain accurate

Worker Training Requirements

OSHA and industry best practices require comprehensive training for personnel working in C1D2 areas:

- Understanding of hazardous area classifications and what they mean

- Recognition of equipment certification markings

- Proper use of certified equipment (especially communication devices)

- Emergency response procedures for ventilation failure or gas release

- Hot work permit procedures if any maintenance requires potential ignition sources

- Awareness of changing conditions that could elevate risk levels

Documentation and Compliance

Facilities must maintain:

- Area classification drawings showing all classified areas and their boundaries

- Equipment inventory with certification documentation

- Maintenance records demonstrating ongoing compliance

- Training records for all personnel working in classified areas

- Inspection reports from regular safety audits

Failure to meet these requirements can result in OSHA citations, increased insurance premiums, and most importantly, serious safety incidents.

Industries with C1D2 Hazardous Locations

C1D2 classifications appear across numerous industries where flammable gases and vapors are handled but kept under control. Understanding whether your industry typically includes these areas helps with proper planning and compliance.

Oil & Gas Industry

Common Class 1 Div 2 areas:

- Control rooms and instrument buildings near process units

- Motor control centers with proper ventilation

- Loading rack control stations

- Maintenance shops adjacent to refinery units

- Laboratory spaces with enclosed chemical analysis equipment

- Compressor buildings with ventilation systems

Typical materials present: Natural gas, propane, butane, gasoline vapors, hydrogen sulfide

Chemical Manufacturing

Common Class 1 Div 2 areas:

- Chemical storage warehouses with sealed drums

- Quality control laboratories

- Packaging areas for sealed containers

- Raw material receiving areas

- Control rooms near reactors

- Maintenance corridors with proper barriers

Typical materials present: Solvents, acetone, ethanol, toluene, benzene, various chemical vapors

Paint and Coating Facilities

Common Class 1 Div 2 areas:

- Paint storage rooms with closed containers

- Mixing rooms with local exhaust ventilation

- Can filling areas (when not actively filling)

- Warehouse storage for sealed products

- Quality testing labs

Typical materials present: Paint thinners, MEK, acetone, xylene, various VOCs

Pharmaceutical Manufacturing

Common Class 1 Div 2 areas:

- Solvent storage areas

- Equipment cleaning rooms

- Alcohol-based product storage

- Extraction areas with closed systems

- Analytical laboratories

Typical materials present: Ethanol, isopropanol, methanol, acetone

Food and Beverage Processing

Common Class 1 Div 2 areas:

- Ethanol storage for extraction processes

- Fermentation areas with controlled ventilation

- Flavor and extract production zones

- Cleaning solution storage areas

Typical materials present: Ethanol, natural gas for heating systems

Automotive and Aerospace

Common Class 1 Div 2 areas:

- Parts cleaning stations with sealed equipment

- Paint storage and preparation areas

- Fuel system testing areas

- Solvent storage rooms

- Composite manufacturing areas using resins

Typical materials present: Gasoline, jet fuel vapors, acetone, MEK, various solvents

Wastewater Treatment Plants

Common Class 1 Div 2 areas:

- Digester control buildings

- Pump stations with proper ventilation

- Gas handling equipment rooms

- Areas adjacent to anaerobic digesters

Typical materials present: Methane, hydrogen sulfide

Does Your Facility Need C1D2 Equipment?

If your facility stores, handles, or processes any flammable liquids or gases—even in sealed containers—you likely have C1D2 areas. A professional hazardous area classification study can:

- Identify all classified locations in your facility

- Determine appropriate Class, Division, and Group designations

- Establish boundaries for each hazardous area

- Specify equipment requirements for each zone

- Ensure compliance with NEC and OSHA regulations

Working without proper classification puts workers at risk and exposes your organization to regulatory penalties.

C1D2 Certified Communication Devices

One of the most challenging aspects of operating in C1D2 environments is maintaining effective worker communication while ensuring all devices meet safety requirements.

The Communication Challenge in Hazardous Areas

Workers in these locations need reliable communication for:

- Coordinating operations across different zones

- Emergency response and evacuation procedures

- Maintenance and troubleshooting support

- Daily operational check-ins and status updates

- Reporting abnormal conditions immediately

However, traditional communication devices pose significant challenges in these environments.

Why Standard Smartphones Don’t Work

Most smartphones are NOT certified for C1D2 use because they:

- Generate heat that could exceed temperature classification limits

- Have batteries that can fail and create sparks

- Contain circuits capable of releasing ignition energy

- Lack proper enclosures to contain potential ignition sources

- Cannot be repaired or modified without voiding any safety characteristics

Even smartphones marketed as “intrinsically safe” often come with severe limitations:

- Restrictions on which features can be used in hazardous areas

- Complex mode-switching requirements

- Limited functionality when in “safe” mode

- Risk of user error activating unsafe features

- High costs (often $800-$1,500 per device)

Traditional Two-Way Radios: The Cost Barrier

Legacy two-way radios with C1D2 certification are available but present financial challenges:

Typical costs:

- Basic Class 1 Div 2 two-way radios: $800-$1,200+ per unit

- Radio infrastructure (repeaters, base stations): $10,000-$50,000+

- Ongoing licensing and maintenance costs

- Limited to voice communication only—no digital collaboration

For facilities needing to equip entire workforces (50-500+ workers), these costs become prohibitive, forcing difficult choices between worker connectivity and budget constraints.

Walt Smart Radio: Full-Featured C1D2 Communication

Our Walt Smart Radio is globally certified as a C1D2 device, meaning workers can safely use ALL available features of the device while operating in these national electric code class hazardous locations or any lower classification (Class 2, Class 3, or non-hazardous areas).

Key advantages:

Complete certification with no restrictions:

- Full device functionality available in Class 1 Div 2 environments

- No need to switch modes or disable features

- Voice, text, images, and digital collaboration all certified

- Reduces user error risk from complex safety protocols

Cost-effective deployment:

- Significantly lower per-unit cost than traditional certified radios

- No expensive radio infrastructure required

- Scales easily across entire workforces

- Predictable subscription pricing

Modern digital capabilities:

- Push-to-talk voice communication

- Text messaging and group chats

- Photo and document sharing

- Location tracking (where permitted)

- Integration with existing communication systems

- Cloud-based management and updates

Important limitation: Walt Smart Radio is NOT certified for Class 1 Division 1 environments. For Division 1 areas, workers must use equipment with higher protection levels or follow hot work permit procedures.

Equipment Hierarchy: What Works Where

Understanding which devices can be used in which classifications:

| Device Type | Class 1 Div 1 | Class 1 Div 2 | Class 2 | Class 3 | Non-Hazardous |

|---|---|---|---|---|---|

| Division 1 certified radios | ✓ | ✓ | ✓ | ✓ | ✓ |

| Walt Smart Radio | ✗ | ✓ | ✓ | ✓ | ✓ |

| Standard two-way radios | ✗ | ✗ | ✗ | ✗ | ✓ |

| Regular smartphones | ✗ | ✗ | ✗ | ✗ | ✓ |

Remember: Equipment certified for a more hazardous classification can always be used in less hazardous areas, but never the reverse.

Making the Right Choice for Your Facility for Hazardous Zones

When selecting communication devices for those areas, consider:

- What classifications exist in your facility? If you only have Div 2 and lower, you have more cost-effective options

- How many workers need devices? Cost-per-unit matters more with larger deployments

- What communication features do you need? Voice-only vs. full digital collaboration

- What’s your infrastructure budget? Traditional radio systems require significant upfront investment

- How important is user adoption? Intuitive devices reduce training time and usage errors

Scenarios:

- Storage rooms with sealed drums of flammable liquids

- Areas adjacent to Division 1 locations with proper ventilation

- Closed piping systems containing flammable gases

- Equipment rooms with mechanical ventilation systems

- Loading docks where sealed containers are moved but not opened

Class 1 Div.2 NEC Hazardous Locations

Class 1 identifies hazardous locations where flammable gases or vapors may be present in the air under normal conditions at any time. Any location with this Class 1 hazardous location label distinguishes that those products are present and extra precautions should be taken while in or around the area.

There are two Divisions under the Class 1 classification: Class 1 Div. 1 and Class 1 Div. 2. Regarding hazardous locations, the distinction between the two is if the concentration of the flammable gases and vapors identified in its Class 1 designation is ignitable under normal working conditions or under abnormal working conditions.

If the concentration is enough to ignite under normal conditions, it’s a Class 1 Div. 1 area. If the concentration is enough to ignite under unusual conditions in the area, it’s labeled as Class 1 Div. 2.

A class 1 div 2 hazardous location handles, processes, or uses flammable gases or vapors while meeting strict class 1 div 2 requirements, but they are kept safely confined in designated areas and containers. These areas also have specialized ventilation to keep these products from concentrating enough to become ignitable mixtures. However, under abnormal conditions, such as a container being damaged, the product can escape and ignite.

Regarding a Class 1 Div. 1 hazardous environment, additional precautions are taken to keep workers safe while inside these areas.

Why the Division Matters for Your Facility

The classification directly impacts:

- Equipment costs: Division 1 requires more expensive certified equipment across all electrical and electronic devices

- Operational flexibility: Division 2 allows more standard equipment with proper certification, reducing costs

- Maintenance requirements: Division 1 areas require more frequent inspections and stricter protocols

- Insurance and liability: Proper classification affects your facility’s risk profile and insurance premiums

- Worker safety: Understanding which areas are which helps train workers on appropriate precautions

A Class 1 Div. 2 Smart Radio for Flammable Gases

These designations don’t only apply to locations workers operate in, but the tools they are allowed to use while inside these areas. Every device approved for these designations is also approved for the hazardous areas beneath it.

For example, our Walt Smart Radio is Class 1 Div. 2 certified. While you can’t safely use it in a Class 1 Div. 1 area, you can for a Class 1 Div. 2 workplace, plus any Class 2 and Class 3 environment.

Many legacy radios also reach this designation, however, the price per radio gradually increases with its higher certification. With some radios priced at over $1,200 due to the certification, this financial barrier keeps facilities from equipping their whole workforce.

On the other hand, smartphones typically do not receive a Class 1 Div. 2 classification level. If they do, there are a number of warnings and safety implications to consider before operating in a hazardous area.

With this distinction, Walt Smart Radio is globally certified to safely operate in these areas in its entirety while under normal operating conditions. Users can safely access and use the full digital collaboration capabilities of the platform while in these areas as well.

Class 1 Div 1 vs Class 1 Div 2: Key Differences

Understanding the difference between Class 1 Div 1 and Class 1 Div 2 is essential for workplace safety. The key distinction lies in when flammable gases or vapors are present at ignitable concentrations.

Class 1 Div 1 vs Div 2 comparison:

- Class 1 (Division 1) Flammable gases or vapors are present at ignitable concentrations under normal operating conditions. This represents the highest risk level and requires the most stringent safety measures.

- C1 (Division 2): Flammable gases or vapors are typically confined and only present at ignitable concentrations under abnormal conditions, such as equipment failure or container damage. When comparing Class 1 Div 1 vs Class 1 Div 2 environments, the Division 2 classification allows for more operational flexibility while still maintaining strict safety standards. This is why many industrial facilities operate under class 1 div 2 guidelines, where proper containment and ventilation systems keep hazardous materials under control.

Requirements

To operate safely in this hazardous location, equipment must meet specific class 1 div 2 requirements established by the National Electrical Code (NEC).

Key Class 1 Div 2 requirements include:

- Equipment Certification: All electrical devices must be certified for use in class 1 div 2 hazardous locations. This certification ensures the equipment won’t become an ignition source under normal or abnormal conditions.

- Proper Enclosures: Devices must have appropriate enclosures that prevent sparks or hot surfaces from igniting flammable atmospheres.

- Temperature Ratings: Equipment surface temperatures must remain below the ignition temperature of hazardous substances present in the area.

- Ventilation Systems: NEC Class 1 div 2 electrical requirements in hazardous locations must have adequate ventilation to prevent the accumulation of flammable gases or vapors.

- Worker Training: Personnel must be trained on the specific requirements for their workplace and the proper use of certified equipment.

Frequently Asked Questions

What is Class 2 Div 2?

This refers to hazardous locations where flammable gases or vapors are present but normally confined in closed containers or systems. Under normal conditions, these substances are not present in quantities sufficient to create an explosive atmosphere. The area only becomes hazardous during abnormal conditions such as equipment failure, container rupture, or ventilation system breakdown.

What is a C1D2 hazardous location?

This hazardous location is an area where flammable gases or vapors may be present only under abnormal conditions, such as equipment failure, container rupture, or system breakdown. These locations require certified equipment to prevent ignition sources but operate safely under normal conditions due to proper containment and ventilation systems. Examples include sealed chemical storage rooms, control rooms near refineries, and areas with closed piping systems.

How does this zone differ from Class 1 Div 1?

The primary difference between Class 1 Division 1 and Division 2 is the frequency and concentration of flammable materials:

- Division 1: Hazardous concentrations are present during normal operations, continuously or periodically

- Division 2: Hazardous concentrations only occur under abnormal conditions like equipment failures

This distinction affects equipment requirements, costs, and operational procedures. Division 1 requires more stringent and expensive protection measures, while Division 2 allows more flexibility with proper containment and ventilation.

What equipment can be used in these areas?

Equipment must be:

- Certified by a recognized testing laboratory (UL, CSA, FM Global, IECEx)

- Rated for the specific Class, Division, and Group present

- Marked with appropriate temperature classification (T-code)

- Protected using approved methods: non-incendive, hermetically sealed, purged/pressurized, intrinsically safe, or explosion-proof

Equipment certified for Division 1 can be used in Division 2 locations, but Division 2 equipment cannot be used in Division 1 areas.

Does this designation or class require explosion-proof equipment?

No, it does NOT always require explosion-proof equipment. “Explosion-proof” is just one protection method suitable for these areas. Division 2 locations can also use:

- Non-incendive equipment (most common for Div 2)

- Hermetically sealed devices

- Purged and pressurized enclosures

- Intrinsically safe circuits

Explosion-proof equipment (required for Division 1) can be used in Division 2 but is typically more expensive than necessary.

What is the difference between NEC and IEC classification systems?

The NEC (National Electrical Code) system, used primarily in the United States, uses Classes and Divisions:

- Class 1, Division 1 or Division 2 (gases/vapors)

- Class 2, Division 1 or Division 2 (dusts)

- Class 3, Division 1 or Division 2 (fibers)

The IEC (International Electrotechnical Commission) system, used globally, uses Zones:

- Zone 0, 1, or 2 (gases/vapors)

- Zone 20, 21, or 22 (dusts)

Approximate equivalents:

- Division 1 ≈ Zone 1

- Division 2 ≈ Zone 2

- No NEC equivalent for Zone 0 (most hazardous)

What are Groups in Class 1 hazardous locations?

Groups classify gases and vapors by their ignition properties within Class 1 locations:

- Group A: Acetylene (most hazardous, lowest ignition energy)

- Group B: Hydrogen, manufactured gas

- Group C: Ethylene, cyclopropane

- Group D: Propane, gasoline, natural gas, butane (least hazardous of Class 1)

Equipment must be rated for the specific Group(s) present in your facility.

What do temperature classifications (T-codes) mean?

T-codes indicate the maximum surface temperature equipment can reach, which must be below the ignition temperature of materials present:

- T1: 450°C (842°F) – Most gases

- T2: 300°C (572°F) – Standard applications

- T3: 200°C (392°F) – More sensitive materials

- T4: 135°C (275°F) – Acetaldehyde

- T5: 100°C (212°F) – Low ignition materials

- T6: 85°C (185°F) – Carbon disulfide (most restrictive)

Equipment marked T4 can operate in any area requiring T4, T3, T2, or T1, but cannot be used where T5 or T6 is required.

Can smartphones be used in these areas?

Standard smartphones are NOT certified for use and pose serious safety risks. Some specially designed “intrinsically safe” smartphones exist but typically have significant limitations:

- Restricted features in hazardous mode

- Complex switching procedures

- High costs ($800-$1,500+)

- Risk of user error

Purpose-built certified devices like industrial two-way radios or certified smart radios are recommended for reliable, compliant communication in these environments.

How do you determine if an area is this designation?

Determining area classification requires a formal hazardous area classification study conducted by qualified professionals. The process includes:

- Material assessment: Identify all flammable gases and vapors present

- Source identification: Locate all potential release points

- Release probability analysis: Determine if releases occur during normal or only abnormal conditions

- Ventilation evaluation: Assess adequacy of mechanical or natural ventilation

- Extent calculation: Calculate the distance hazardous concentrations could travel

- Documentation: Create area classification drawings showing all boundaries

This study should be updated whenever processes change, new equipment is installed, or materials are modified.

What is the penalty for non-compliance with hazardous area requirements?

OSHA can issue citations for non-compliance with hazardous location requirements under the General Duty Clause and specific standards. Penalties include:

- Serious violations: Up to $16,131 per violation

- Willful or repeated violations: Up to $161,323 per violation

- Failure to abate: Up to $16,131 per day beyond the abatement date

Beyond financial penalties, non-compliance can result in:

- Increased insurance premiums or loss of coverage

- Facility shutdown orders

- Civil liability from worker injuries

- Criminal charges if negligence leads to fatalities

Most importantly, non-compliance puts workers’ lives at risk.

Do I need a hot work permit in this particular areas?

Yes, hot work (welding, cutting, grinding, or any operation that could produce sparks or flames) in these areas requires a hot work permit. The permit process includes:

- Gas testing to confirm the area is free of flammable concentrations

- Implementation of fire watches

- Availability of fire suppression equipment

- Clearance from a qualified person

- Continuous monitoring during hot work

- Post-work inspection

International Classification: Zone System vs Division System

While this guide focuses on the NEC Class and Division system used in the United States, it’s valuable to understand the international Zone system for global operations or equipment sourcing.

IEC Zone Classification System

The International Electrotechnical Commission (IEC) system uses Zones instead of Divisions:

For gases and vapors:

- Zone 0: Explosive atmosphere present continuously or for long periods (most hazardous)

- Zone 1: Explosive atmosphere likely to occur in normal operation periodically

- Zone 2: Explosive atmosphere not likely to occur, or only for short periods

For combustible dusts:

- Zone 20: Combustible dust cloud present continuously or for long periods

- Zone 21: Combustible dust cloud likely to occur periodically

- Zone 22: Combustible dust cloud not likely to occur or only briefly

Approximate Equivalencies

While not perfect matches, general equivalencies help understand both systems:

| NEC System | IEC Zone System | Risk Level |

|---|---|---|

| No equivalent | Zone 0 | Highest (continuous presence) |

| Class 1 Division 1 | Zone 1 | High (normal operations) |

| Class 1 Division 2 | Zone 2 | Moderate (abnormal c |

| No equivalent | Zone 20 | Highest (continuous dust cloud) |

| Class 2 Division 1 | Zone 21 | High (normal operations) |

| Class 2 Division 2 | Zone 22 | Moderate (abnormal conditions) |

Equipment Protection Levels (EPL)

The IEC system also uses Equipment Protection Levels:

- EPL Ga: Very high protection (Zone 0 suitable)

- EPL Gb: High protection (Zone 1 suitable)

- EPL Gc: Enhanced protection (Zone 2 suitable)

For dusts:

- EPL Da: Very high protection (Zone 20)

- EPL Db: High protection (Zone 21)

- EPL Dc: Enhanced protection (Zone 22)

Why Understanding Both Systems Matters

Global equipment sourcing: Many manufacturers produce equipment certified to IEC standards. Understanding equivalencies helps evaluate if international equipment meets your NEC requirements.

International facilities: Companies with operations in multiple countries need to comply with local standards. Understanding both systems facilitates consistent safety practices globally.

Harmonization trend: The US is gradually moving toward greater alignment with IEC standards. The NEC increasingly references IEC protection methods and terminology.

Equipment markings: You may encounter equipment marked with both systems (e.g., “Class I, Division 2, Groups C, D / Zone 2, IIC”).

Taking Action: Next Steps for Your Facility

Assess Your Current Situation

If you operate a facility that handles, stores, or processes flammable materials, take these steps:

- Conduct or update your hazardous area classification study

- Required every 3-5 years or when processes change

- Must be performed by qualified professionals

- Creates the foundation for all other safety measures

- Inventory all equipment in classified areas

- Document certification markings

- Verify equipment matches area classification requirements

- Identify any non-compliant equipment requiring replacement

- Review ventilation systems

- Ensure adequate capacity for current operations

- Test monitoring and alarm systems

- Verify interlocks function properly

- Audit worker training

- Confirm all personnel understand hazardous area basics

- Verify workers can identify classification markings

- Test emergency response knowledge

- Evaluate communication capabilities

- Assess how workers currently communicate in classified areas

- Identify gaps in coverage or connectivity

- Consider upgrading to certified modern communication devices

Ensuring Worker Safety and Compliance

Proper management of these hazardous locations requires ongoing attention:

Engineering controls:

- Maintain containment systems to prevent releases

- Keep ventilation systems operating effectively

- Use properly certified equipment throughout

Administrative controls:

- Implement hot work permit systems

- Establish maintenance procedures for classified areas

- Maintain current area classification drawings

- Document all equipment certifications

Personal protective equipment:

- Provide appropriate PPE for potential exposures

- Ensure workers understand when and how to use PPE

- Maintain and inspect PPE regularly

Continuous improvement:

- Review incidents and near-misses