Manufacturing facilities are high-risk environments where heavy machinery and fast production cycles leave little room for error. When communication breaks down or hazards go unnoticed, routine tasks turn into safety concerns that slow operations and put workers at risk. Establishing strong, consistent safety practices in manufacturing helps protect your teams and keep production running smoothly. In this guide, we’ll show you 13 modern ideas to implement today.

Key Takeaways

- Safety in manufacturing is the ongoing process of reducing operational risks through clear communication, consistent procedures, and proactive hazard awareness across facilities.

- Strong safety practices in manufacturing help prevent incidents and keep production moving without avoidable interruptions.

- Tools that support multilingual communication, real-time alerts, and location tracking strengthen safety culture and help teams respond faster during high-risk situations.

- The Walt® Smart Radio System by weavix® enhances safety in manufacturing plants by giving teams instant communication, visual reporting, and translation tools designed for fast, coordinated response.

What Is Safety in the Manufacturing Industry?

Safety in the manufacturing industry is the collection of processes, protocols, and behaviors designed to protect workers from injuries, equipment-related hazards, and environmental risks. Safety practices encompass:

- Proper personal protective equipment (PPE)

- Machine guarding and safe equipment operation

- Lockout or tagout procedures for maintenance and repairs

- Safe material handling and storage

- Clear information sharing with advanced manufacturing communication systems

- Real-time visibility into what’s happening on the floor

- Emergency response through mass notification systems

- Routine inspections and safety audits

Top 13 Safety Improvement Ideas in Manufacturing

Even minor safety issues can slow production or pull teams off the floor, causing downtime, delays, and added operational strain. For plant managers, maintaining a safe environment is what helps keep work moving and prevents avoidable disruptions.

These 13 safety improvement ideas in manufacturing offer practical ways to strengthen operational reliability and ensure workers stay protected in high-risk areas of the plant.

1. Improve Workplace Hazard Awareness and Reporting

In a fast-moving manufacturing facility, it’s easy for safety hazards to go unnoticed. Improving awareness and reporting helps your workforce identify issues early and address them before they become injuries.

To strengthen hazard awareness and reporting:

- Provide quick training on spotting equipment, ergonomic, and environmental risks

- Place clear signage in high-risk areas

- Make reporting accessible through modern two-way radio systems

- Encourage near-miss reporting to uncover hidden problems

2. Implement Clear and Consistent Safety Protocols

Clear safety protocols help eliminate confusion during operations and ensure every worker follows the same expectations, no matter the shift or job role. When you write down your current safety practices in manufacturing and reinforce them regularly, teams can respond to hazards more confidently and keep production running without unnecessary interruptions.

3. Provide Comprehensive Safety Training for Every Worker

Safety training ensures workers understand how to operate equipment, move through the facility, and respond to incidents without hesitation. According to Vector Solutions, nearly 40% of industrial workers say safety in manufacturing is only discussed after an incident occurs, which shows how often critical information reaches teams too late. Comprehensive training helps close that gap by giving workers the knowledge they need before issues escalate.

Training should cover:

- Proper equipment use and machine guarding

- Emergency procedures and evacuation routes

- PPE requirements and inspection

- Hazard identification and reporting

- Communication expectations in high-risk areas

4. Improve Communication with Real-Time, Facility-wide Connectivity

Real-time, facility-wide connectivity helps maintain a safe workplace by preventing miscommunication and ensuring information reaches the right people when it matters.

Strong connectivity also supports connected workers, giving every team member access to the same updates, alerts, and instructions. This capability keeps crews aligned, improves coordination between shifts, and helps supervisors respond faster when something needs attention.

Learn how to improve manufacturing communication.

5. Equip Workers with the Proper PPE for Their Roles

Proper PPE is one of the simplest ways to maintain a safe work environment. Workers in manufacturing may need hearing protection, cut-resistant gloves, face shields, respirators, or high-visibility gear, depending on their tasks and exposure levels.

Along with physical PPE, some facilities also rely on devices designed for hazardous locations, including intrinsically safe radios for workers operating around flammable materials or explosive atmospheres.

6. Reduce Risks Through Better Housekeeping and Workspace Organization

Cluttered walkways, spilled materials, and poorly organized workstations are some of the most common contributors to slips, trips, and other preventable incidents. Strong housekeeping is a core part of safety in manufacturing plants, helping teams move safely through high-traffic areas and reducing the chance of workers encountering unexpected hazards during their shift.

7. Prevent Machine-Related Injuries with Proper Guarding and Maintenance

Heavy machinery introduces risks that require proper guarding, clear procedures, and consistent upkeep to keep workers safe. These controls form an important part of safety initiatives in manufacturing, helping protect teams from moving parts, pinch points, and stored energy that may cause serious harm if not managed correctly.

Routine inspections and preventive maintenance reduce the chance of unexpected equipment issues and help keep machines operating safely. When guards stay in place and equipment remains in good condition, workers can perform their tasks with more confidence and fewer interruptions to production.

8. Use Workforce Danger Alert Systems for Faster Emergency Response

Your workforce needs a reliable way to notify the right people as soon as an emergency happens. Alerting systems help teams respond faster by delivering instant notifications about injuries, equipment issues, environmental risks, or other urgent situations anywhere in the facility.

Different industries rely on these systems in different ways, but the goal is the same: faster awareness, quicker action, and a safer operation for every worker.

| Industry | How alerts improve safety in manufacturing |

|---|---|

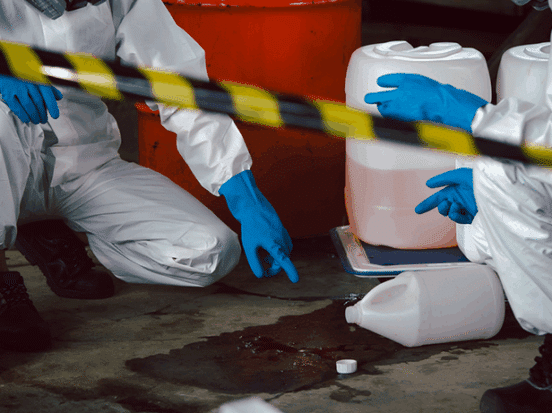

| Chemichal Manufacturing | Immediate visibility into leaks, exposure risks, or unexpected chemical reactions. |

| Food and beverage processing | Faster awareness of equipment jams, contamination risks, or temperature issues. |

| Automotive manufacturing | Early detection of equipment faults, line stoppages, or electrical hazards during assembly. |

9. Strengthen Safety Culture in Manufacturing Through Leadership and Daily Reinforcement

When supervisors, managers, and team leads consistently commit to safety by following protocols, addressing issues quickly, and communicating expectations, workers are more likely to stay aligned and engaged in safe practices throughout their shift.

10. Support Multilingual Teams With AI Language Translation Tools

Language gaps slow communication and lead to misunderstandings that affect safety in manufacturing. AI language translation tools help workers understand important updates, instructions, and hazard information in real time, reducing delays and ensuring everyone receives the same message, no matter what language they speak.

See how AI translation benefits manufacturing and construction.

11. Conduct Frequent Safety Audits and Corrective Action Reviews

Regular safety audits give plant managers a clear view of what’s working and what needs attention across the floor. These evaluations help verify whether teams are following safety practices in manufacturing and uncover conditions — like worn equipment, blocked walkways, or outdated procedures — that could lead to incidents if left unaddressed.

Key steps in the audit process include:

- Reviewing equipment condition and housekeeping standards

- Verifying proper PPE use and machine guarding

- Checking the accuracy and accessibility of safety documentation

- Tracking corrective actions until completion

12. Leverage Location Tracking to Improve Accountability and Evacuations

Location tracking gives supervisors real-time visibility into where crews are working, which helps improve accountability across large or fast-moving manufacturing environments. Modern walkie-talkies with GPS capabilities allow leaders to monitor worker positions, coordinate tasks more effectively, and keep a closer watch on high-risk areas.

Keep learning: 10 reasons to give every worker an industrial radio.

13. Capture Safety Data to Identify Trends and Reduce Future Incidents

Capturing safety data gives plant managers a clear view of where risks arise and how frequently issues occur across the facility. Smart walkie-talkies for manufacturing help teams document hazards, near-misses, and equipment concerns as they happen, creating a reliable record that shows patterns supervisors might not notice during day-to-day operations.

Increase Safety in Manufacturing Plants with the Walt® Smart Radio System by weavix®

Manufacturing environments move fast, and crews need a reliable way to share information, report issues, and respond to unexpected situations. The Walt® Smart Radio System by weavix® helps increase safety in manufacturing plants by giving every worker instant access to clear communication, visual messaging, and real-time translation in one rugged device built for industrial conditions.

As part of our safety solutions, Walt streamlines coordination across large facilities and reduces delays that often lead to safety risks.

At Aspire Bakeries, for example, Walt improved maintenance response times by 8%, preventing costly line stoppages and eliminating lengthy cross-plant walks through instant photo and video communication. During a construction incident, rapid communication through Walt helped avoid an unnecessary evacuation and kept production running safely.

Contact us to learn how Walt can help you keep workers protected and operations stable.

Frequently asked questions

What’s the importance of safety in the manufacturing industry?

The importance of safety in the manufacturing industry is that it protects workers, prevents workplace injuries, and ensures consistent productivity across your operation. Because manufacturing environments often involve hazardous materials, heavy equipment, and fast-paced workflows, strong safety protocols minimize risks and keep workers safe.

What are the most common safety hazards in the manufacturing industry?

The most common safety hazards in the manufacturing industry come from the physical, chemical, and operational demands of the workplace. These potential hazards escalate quickly without the right safety protocols and workforce danger alert systems in place to warn teams about emerging risks.

Key safety hazards in manufacturing include:

- Machinery-related risks (moving parts, pinch points, lockout or tagout failures)

- Slips, trips, and falls due to poor housekeeping or obstructed walkways

- Exposure to hazardous materials and chemical substances

- Ergonomic strain from repetitive motions or improper lifting

- Electrical hazards from equipment, wiring, or maintenance issues

- Noise exposure that impacts communication and awareness

Addressing these workplace hazards through proactive inspections, updated safety equipment, and regular training helps create a safer work environment and reduces preventable workplace injuries.

What are the top safety KPIs in manufacturing?

The top safety KPIs in manufacturing include:

- Total recordable incident rate (TRIR): TRIR measures the number of OSHA-recordable injuries per 100 full-time workers. This KPI provides a high-level view of overall workplace safety and incident frequency.

- Lost-time injury rate (LTIFR): LTIFR reflects how often injuries result in missed workdays, showing the severity of incidents and their impact on productivity and worker wellbeing.

- Near-miss reports submitted: Near-miss data highlights situations that could have caused harm but didn’t, offering critical visibility into potential hazards. High reporting rates signal a strong safety culture in manufacturing and proactive risk awareness.

How to ensure compliance with safety regulations in manufacturing?

To ensure compliance with safety regulations in manufacturing, you must understand OSHA standards and conduct ongoing safety training for your workforce. Many organizations implement structured safety programs that outline responsibilities, required training, and procedures for reporting concerns.

To stay compliant with safety regulations long-term, manufacturing leaders should:

- Conduct regular safety audits and assessments

- Maintain accessible records of incidents and training

- Reinforce safety procedures during daily operations

- Equip workers with the proper personal protective equipment (PPE)

What are some best practices for multilingual safety protocols in manufacturing?

The best practices for multilingual safety protocols in manufacturing involve making information accessible to workers of all language backgrounds. Manufacturing and safety leaders who manage a multicultural team should:

- Offer training materials, signage, and safety procedures in multiple languages

- Include clear visual safety cues, such as diagrams, color coding, and icons

- Use a language translation device or bilingual trainers during safety training

- Provide real-time translation tools that overcome language barriers

These practices help you strengthen safety protocols and build a more inclusive, high-performing safety culture in the manufacturing indust